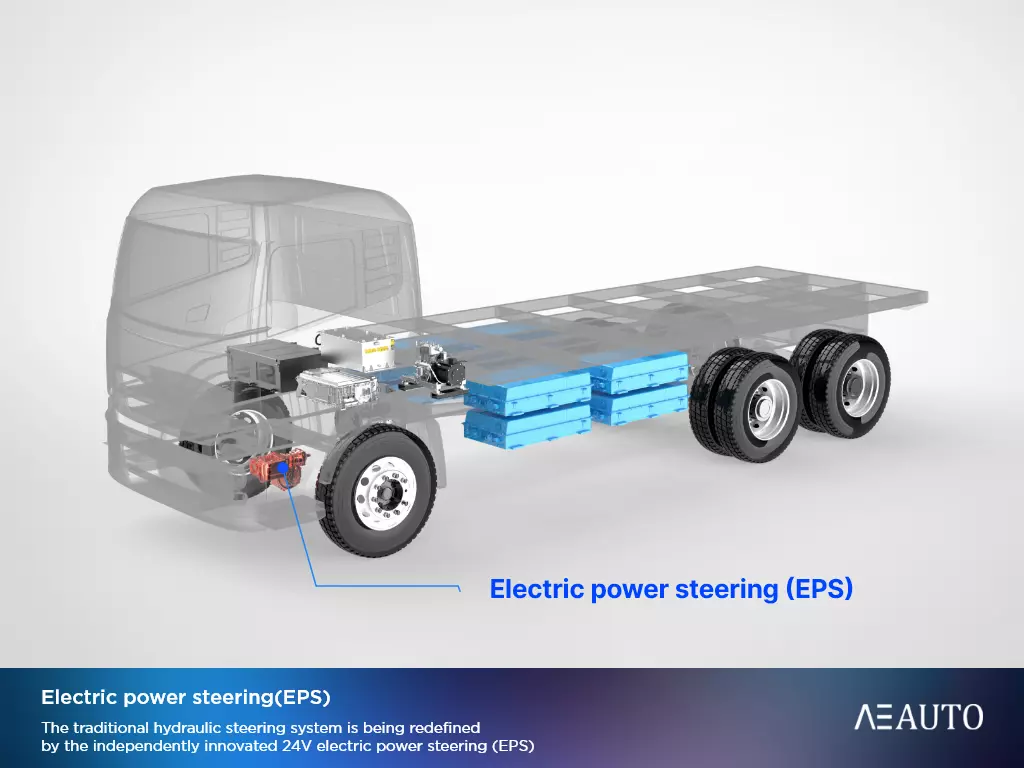

“When the 1,000th heavy truck equipped with AEAUTO‘s 24V EPS system crossed the Taklimakan Desert, the steering wheel in the cab was undergoing a silent revolution – it was no longer a mechanical arm driven by hydraulic oil, but an intelligent terminal carrying 2.4 million kilometers of road test data…” As a witness who has been deeply involved in the field of intelligent chassis for commercial vehicles for 15 years, AEAUTO has witnessed and promoted a key turning point: the traditional hydraulic steering system is being redefined by the independently innovated 24V electric power steering (EPS), behind which is the deep logic of the intelligent transformation of commercial vehicles.

The electrification of commercial vehicles has never been just an innovation of the power system. When autonomous driving moves from the laboratory to trunk logistics, and when the carbon neutrality goal forces the optimization of energy consumption per watt, the steering system, a “silent executor”, begins to show its strategic value. AEAUTO latest mass-produced 24V electric power steering (EPS) is the engineering answer to this industrial change. In actual testing in the northwest desert, the system withstood the challenge of a 70°C temperature difference. In the port AGV collaborative scenario, the torque response accuracy of 0.05 seconds makes heavy-load control a breeze.

This solution, which engineers call the “universal chassis for steering systems”, hides AEAUTO’s technological innovation in five dimensions:

(1) Full-scenario compatible architecture: deeply compatible with traditional hydraulic and recirculating ball steering systems, adaptable to 90% of commercial vehicle platforms, and supports seamless switching of mechanical/electrical dual channels.

(2) Extremely fast and precise control: steering wheel control response ≤50 ms, angular velocity peak 540°/s, angle accuracy of 0.05°, achieving micron-level trajectory correction under high-speed and heavy-load conditions.

(3) Environmental self-healing algorithm: multiple intelligent working mode modes are automatically switched, maintaining ±0.1° angle stability in the temperature range of -40°C to 85°C, salt spray corrosion and sandstorm environments.

(4) Real-time data center: 10ms communication interval synchronously transmits 18-dimensional data such as steering wheel angle and motor torque, supporting the vehicle controller to dynamically optimize the steering strategy.

(5) Evolvable ecological platform: pre-embedded OTA upgrade channel and 12 sets of sensor interfaces, compatible with ADAS function iterations such as LKA/ICA, and build a “software-defined steering” ecological base.

It is worth noting that this system demonstrates a new paradigm of Chinese intelligent manufacturing – AEAUTO did not simply copy the technical path of passenger cars, but reconstructed the human-machine engineering balance of commercial vehicles based on 2.4 million kilometers of actual road test data. In a leading logistics fleet in Northwest China, the steering failure rate of vehicles equipped with AEAUTO electric power steering (EPS) decreased by 83%; on the Guangzhou BRT rapid bus line, drivers got a car-level control experience on 12-meter models. These cases confirm the essential value of technology upgrades: it is not an arms race of parameter tables, but makes every turn of the steering wheel carry a safer arrival.

As the first company in China to achieve mass production of 24V electric power steering (EPS), AEAUTO is writing a new industrial narrative for commercial vehicle intelligent chassis. After obtaining CE functional safety certification in 2023, its products have entered the European heavy-duty truck supply chain system. This technical path of “starting from Chinese working conditions and evolving towards global standards” is providing a replicable innovation sample for the industry.

AEAUTO’s industry insights:

(1) The intelligence of commercial vehicles must be based on actual operating scenarios and reject “technology surplus”

(2) Reliability is more important than advancement, and extreme environment verification is the core barrier of products

(3) Smart chassis is the key carrier of vehicle-road collaboration, and space for technology iteration must be reserved

Standing at the node of a century of transformation in commercial vehicles, AEAUTO will continue to deepen its roots in the field of smart chassis. When 24V electric power steering (EPS) began to be installed in batches, what we saw was not only the evolution of the steering wheel, but also the determination of a Chinese smart manufacturing company to redefine industry standards – there is no golden template to learn from, only a deep understanding of complex working conditions and the ultimate pursuit of “zero defect delivery”.

What do you think of the key technological breakthroughs in the process of commercial vehicle intelligence? Welcome to discuss with us the growth path of the “hidden champion” of China’s automotive electronics.